It condenses a normally long process into the space of a few minutes. I am investigating the possibility of fitting a dc servo / control system to the leadscrew of my denford (southbend sized) lathe to allow me to cut any pitch of thread.

What Have I Gotten Myself Into Cnc Lathe Conversion - Part 1

Easier than ever to use while also giving you the ability to make cuts that are even more accurate.

Diy cnc lathe conversion. Basically what i want is an electronic gearbox. Conversion kits will make the cnc jr. Most conversions will benefit from upgrading to ball screws, but this is at your discretion depending on how much time and money you are willing to spend.

It’s not really a fair comparison to put this little guy against tormach’s lathe. A cnc conversion kit is a set of tools and hardware components that is mounted on a manual mill/lathe/grinder to automate its movements. The retrofit kits are able to simplify complicated plans, such as the production of precision cuts, and their complex measurements.

Having your own cnc machine converted using lathe cnc conversion or mill cnc conversion means you can cut off these third parties and have higher profit margins. If you already own a mill or lathe, cnc conversion using a cnc lathe conversion kit can also boost your roi as parts are produced using the same process every time. All of this goes away with a cnc conversion and i will use a pendant to control it.

The kit offers ample machining power, repeatability, and convenience, with this kit installed, you'll be able to use single point cutting tools to eliminate the need for form tooling and the need for the oprator to. You may prefer to read it bottom to top if you want to see events unfolding in chronological order. The enclosure is in the making.

It contains a 3 position changeover switch, a potentiometer, c3 index pulse card, and an ethernet breakout board. If you’re into diy cnc machines, have a. You can of course also put together your own set.

The cnc lathe 1340 conversion kit is available as a complete retrofit kit ready to install on your own manual enco, birmingham, jet, nova, grizzly, or similar 13 x 40 lathe. These cnc conversion plans were created by ronald j. There is no reason to have cranks and they just get in the way.

Most conversions will yield a mini or small cnc lathe that is usable at the home or work shop level, yet still produces a greater output than manual lathes. The gear box cover is converted into the operator control for the cnc conversion. What is a cnc conversion kit?

You also need a motor to. This is the update video for my conversion of an old craftsman lathe into cnc control. Since a few years it is also possible to connect a cnc very easily via usb.

Since i could not wait to sartup the machine i temporarily mounted all the drivers and power supply on a open board. Instead, i am converting it to a gang or turret style cnc lathe with vfd and controlled by mach 3. Lathe leadscrew cnc conversion :

It was an interesting quest for sure, but it claimed 6 month of my life, and while. The process of converting a manual machine into cnc using the tools provided in cnc conversion kits is called cnc conversion. Cnc lathes don’t have the tool turned upside down keep chips flying in your face(they are already enclosed) but rather to aid in chip evacuation so.

I use a step down converter to convert the 36 volt dc into 5 volt dc. Plus, it’s got an awesome gang tooling and sweet 8 station turret as well. Additionally we have an index dial to mount to the spindle shaft, a mounting block for the c3 sensor head, and an estop module.

If you're thinking of converting your tired lathe or mill to cnc, i recommend you do so as it can be a fun and intensely rewarding project. Grizzly g0704 cnc conversion kit and how to use it One thing i still remember vividly from the days of the cnc mill conversion is how i wished i had spent some money on a cnc kit that someone had already vetted, rather than trying to save a few bucks and doing it all myself.

The tormach is in a different class as it is bigger, heavier, and more rigid. It’s written blog style, with the newest entries at the top. This is a complete set of.

I started by taking off the lead screws, x axis compound etc off. I have found taig sized examples using stepper motors on the web but not. No drilled holes, no m.

Before you do, it's probably a good idea to consider what you typically use it for and whether a cnc conversion will help you do it better or faster. Cnc conversion plans 2395 plans to add cnc to a mini lathe.

Lathe Cnc Conversion Tech-skill

Mid-size Conversion Kits Microkinetics

Lathe - Electronic Lead Screw - Arduino Project Hub

Cnc Fusion - Cnc Conversion Kits For Benchtop Lathes And Mills - Httpwwwcncfusioncom Diy Cnc Cnc Cnc Router Projects

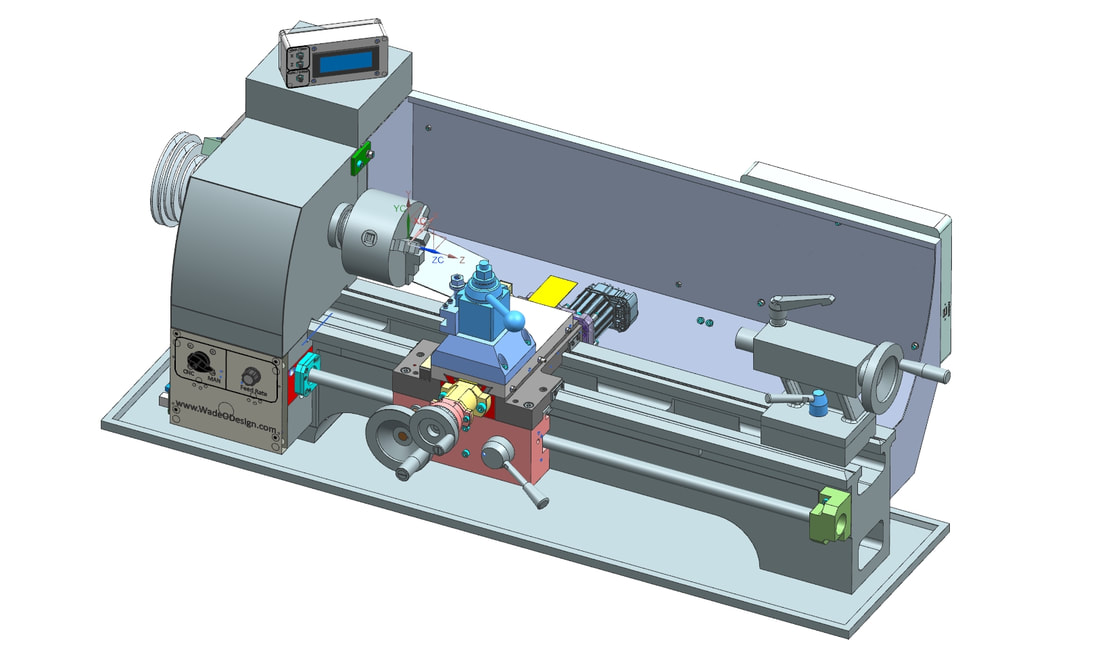

Cnc Lathe Design Details - Wadeo Design

Converting A 13x40 Manual Lathe To Cnc With Servos And Mach3 The Hobby -machinist

Cnc Lathe Conversion Tool Change Test - Youtube

Taig Micro Lathe Cnc Conversion

Mini Torno Mini Lathe Home Made - Youtube Lathe Cnc Lathe Belt Sander

Logan Cnc Lathe Conversion

Logan Cnc Lathe Conversion

Cnc Your Mini Lathe Video 100 - Youtube

Cnc Lathe Jim Hannons Blog

712 Mini Lathe Conversion To Cnc Jims Embeddedtronics

Diy Cnc Lathe - Youtube

Cnc Lathe Conversion - Make

Lathe Cnc Upgrade Is Nothing To Shake A Turned Stick At Hackaday

Lathe Cnc Conversion History - Cnccookbook Be A Better Cncer

28 Cnc Conversion Ideas Cnc Diy Cnc Cnc Lathe